Навіть на засіданні гуртка науково-технічної англійської мови Sci-Tech Talks торкаємось прикладних фахових тем:

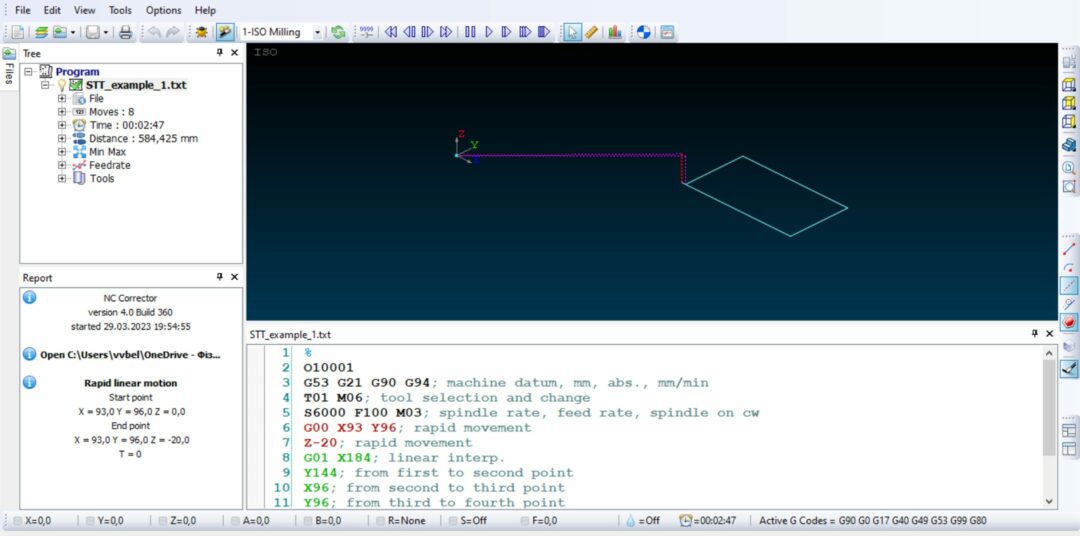

In today’s STT 2.0 meeting, we continued the topic of CNC and considered a simple program in G-code with explanations of the calculations of coordinates of motion. It involves milling sides of a part 80×40 mm with a ⌀8 mm end mill.

Also, we watched a short video about the operation of the tool changer of a CNC milling machine.

Here is the simple program that we considered with comments.

%

O10001

G53 G21 G90 G94; machine datum, mm, abs., mm/min

T01 M06; tool selection and change

S6000 F100 M03; spindle rate, feed rate, spindle on-cw

G00 X93 Y96; rapid motion

Z-20; rapid motion down

G01 X184; linear interpolation

Y144; from first to second point

X96; from second to third point

Y96; from third to fourth point

M05 G00 Z0; spindle stop, rapid up

X0 Y0; rapid to the initial point

%The attached image shows the visualization of motions according to this program in the “NC Corrector” software.